A place where your imagination

is fabricated into reality

A place where your imagination

is fabricated into reality

A place where your imagination

is fabricated into reality

Samsung Foundry Business Samsung Foundry Business Samsung Foundry Business

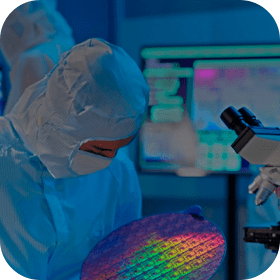

Samsung Foundry retains deep expertise in manufacturing system semiconductors for customers. We aim to become a ‘Total Foundry’, not only drawing on our state-of-the-art process technologies to produce chips for global fabless clients but also providing comprehensive solutions through our Library/PDK (Process Design Kit)/DM (Design Methodology)/Design Service infrastructure. We are preparing to bring innovative technologies to the market faster by producing high-quality products as efficiently as possible through state-of-the-art production facility automation. Samsung Foundry retains deep expertise in manufacturing system semiconductors for customers. We aim to become a ‘Total Foundry’, not only drawing on our state-of-the-art process technologies to produce chips for global fabless clients but also providing comprehensive solutions through our Library/PDK (Process Design Kit)/DM (Design Methodology)/Design Service infrastructure. We are preparing to bring innovative technologies to the market faster by producing high-quality products as efficiently as possible through state-of-the-art production facility automation. Samsung Foundry retains deep expertise in manufacturing system semiconductors for customers. We aim to become a ‘Total Foundry’, not only drawing on our state-of-the-art process technologies to produce chips for global fabless clients but also providing comprehensive solutions through our Library/PDK (Process Design Kit)/DM (Design Methodology)/Design Service infrastructure. We are preparing to bring innovative technologies to the market faster by producing high-quality products as efficiently as possible through state-of-the-art production facility automation.

Leading innovation and the future with Samsung Foundry Leading innovation and the future with Samsung Foundry Leading innovation and the future with Samsung Foundry

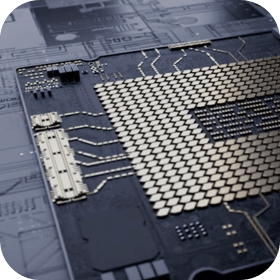

Samsung Foundry has made remarkable progress in semiconductor technology, reducing the process size from 28nm in 2012 to 3nm in 2022. We are constantly pushing the boundaries of semiconductor technology, providing a range of process technologies that offer significant improvements in power, performance, and scalability. From legacy processes to cutting-edge advanced processes, we are committed to taking chip performance to new heights across various industries. Samsung Foundry has made remarkable progress in semiconductor technology, reducing the process size from 28nm in 2012 to 3nm in 2022. We are constantly pushing the boundaries of semiconductor technology, providing a range of process technologies that offer significant improvements in power, performance, and scalability. From legacy processes to cutting-edge advanced processes, we are committed to taking chip performance to new heights across various industries. Samsung Foundry has made remarkable progress in semiconductor technology, reducing the process size from 28nm in 2012 to 3nm in 2022. We are constantly pushing the boundaries of semiconductor technology, providing a range of process technologies that offer significant improvements in power, performance, and scalability. From legacy processes to cutting-edge advanced processes, we are committed to taking chip performance to new heights across various industries.

Advanced and collaborative technologies Advanced and collaborative technologies Advanced and collaborative technologies

Samsung Foundry is focusing on developing cutting-edge under 3nm GAA (Gate All Around) process technology, accelerating the implementation of EUV process for mass production, and establishing a technological super-gap by developing state-of-the-art packaging technologies. In addition, the SAFE™ program enables competitive SoC design through cooperation between Samsung Foundry, partners, and customers. Samsung Foundry is focusing on developing cutting-edge under 3nm GAA (Gate All Around) process technology, accelerating the implementation of EUV process for mass production, and establishing a technological super-gap by developing state-of-the-art packaging technologies. In addition, the SAFE™ program enables competitive SoC design through cooperation between Samsung Foundry, partners, and customers. Samsung Foundry is focusing on developing cutting-edge under 3nm GAA (Gate All Around) process technology, accelerating the implementation of EUV process for mass production, and establishing a technological super-gap by developing state-of-the-art packaging technologies. In addition, the SAFE™ program enables competitive SoC design through cooperation between Samsung Foundry, partners, and customers.

Effective quality management Effective quality management Effective quality management

Samsung Foundry provides an efficient quality system and delivers the best products and services to meet customers’ requirements and expectations through a great quality management system, reliable supply chain security, and mass production quality control. Samsung Foundry provides an efficient quality system and delivers the best products and services to meet customers’ requirements and expectations through a great quality management system, reliable supply chain security, and mass production quality control. Samsung Foundry provides an efficient quality system and delivers the best products and services to meet customers’ requirements and expectations through a great quality management system, reliable supply chain security, and mass production quality control.

Samsung Foundry continues to lead the industry by innovating advanced process technologies across both mature and leading-edge nodes in the AI era.

Utilizing its I-Cube and X-Cube heterogeneous integration technologies, Samsung Foundry provides advanced turnkey packaging services that meet the high-bandwidth, high-capacity, and low-power demands of the AI era.

With its SAFE™ partnership, Samsung Foundry has created the most trusted foundry ecosystem. Together with its partners, including IP, EDA, Cloud, DSP, OSAT, and MDI Alliance, Samsung Foundry optimizes the entire process from design to application-specific production. This enables tailored, advanced semiconductor development for our customers.

Samsung Foundry significantly improves production cycles and yields through smart fab operations and possesses flexible mass production capabilities for both legacy and next-generation advanced semiconductors based on our global foundry network.

Through dedicated teams for each customer and optimized Samsung AI solutions, Samsung Foundry provides process node options that meet the demands of various applications, such as HPC, mobile (5G), automotive, and IoT.

Our site uses cookies. We’d also like to set optional cookies to give you the best experience and provide you relevant advertising. you can choose to manage your preferences or accept all cookies. You can also read our Privacy Policy and Cookie Policy for more information.

This site uses cookies to personalise your experience, analyse site traffic. By Clicking Accept or continuing to browse the site you are agreeing to our use of cookies.

You can read our Privacy Policy and Cookie Policy for more information.

We use cookies to improve you experience on our website and to show you experience on our website and to show you relevant advertising, manage your settings for our cookies below.

These cookies are essential as they enable you to move around the website. This category cannot be disabled.

| Company | Domain |

|---|---|

| Samsung Electronics | semiconductor.samsung.com, image.semiconductor.samsung.com, smetrics.samsung.com |

These cookies collect information about how you use our website, for example which pages you visit most often. All information these cookies collect is used to improve how the website works.

| Cookie | Domain |

|---|---|

| ajax.googleapis.com, apis.google.com, calendar.google.com, developers.google.com, docs.google.com, google.com, maps.googleapis.com, spreadsheets.google.com, www.google.com, www.google.ie | |

| www.google-analytics.com, www.googletagmanager.com, www.gstatic.com | |

| Adobe | assets.adobedtm.com |

These cookies allow our website to remember choices you make (such as your user name, language or the region you are in) and tailor the website to provide enhanced features and content for you.

| Cookie | Domain | Purpose |

|---|---|---|

| Akamai | 176-34-86-175_s-23-203-249-81_ts-1604430438-clienttons-s.akamaihd.net, 176-34-86-175_s-23-203-249-81_ts-1604432488-clienttons-s.akamaihd.net, 176-34-86-175_s-23-203-249-90_ts-1604428164-clienttons-s.akamaihd.net, 176-34-86-175_s-95-101-143-18_ts-1604428258-clienttons-s.akamaihd.net, 176-34-86-175_s-95-101-143-24_ts-1604428321-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604425495-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604425563-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604425669-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604427540-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604427617-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604427664-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604427922-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604439090-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604439174-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604441206-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-81_ts-1604441267-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-90_ts-1604425484-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-90_ts-1604425610-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-90_ts-1604427737-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-90_ts-1604427797-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-90_ts-1604438922-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-90_ts-1604438968-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-90_ts-1604439033-clienttons-s.akamaihd.net, 34-242-207-243_s-23-203-249-90_ts-1604441023-clienttons-s.akamaihd.net, 34-242-207-243_s-95-101-129-82_ts-1604425732-clienttons-s.akamaihd.net, 34-245-202-11_s-23-203-249-81_ts-1604425513-clienttons-s.akamaihd.net, 34-245-202-11_s-23-203-249-81_ts-1604427569-clienttons-s.akamaihd.net, 34-245-202-11_s-23-203-249-90_ts-1604425365-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-81_ts-1604424915-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-81_ts-1604425000-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-81_ts-1604425155-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-81_ts-1604425567-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-81_ts-1604427446-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-81_ts-1604429495-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-90_ts-1604424817-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-90_ts-1604424939-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-90_ts-1604427359-clienttons-s.akamaihd.net, 34-246-182-217_s-23-203-249-90_ts-1604429563-clienttons-s.akamaihd.net, 34-246-182-217_s-95-101-129-82_ts-1604425062-clienttons-s.akamaihd.net, 34-246-182-217_s-95-101-143-18_ts-1604429398-clienttons-s.akamaihd.net, 34-246-182-217_s-95-101-143-24_ts-1604429274-clienttons-s.akamaihd.net, 34-246-182-217_s-95-101-143-24_ts-1604429365-clienttons-s.akamaihd.net, 34-246-182-217_s-95-101-143-24_ts-1604429616-clienttons-s.akamaihd.net, 364bf52c.akstat.io, 364bf5fa.akstat.io, 364bf6cc.akstat.io, 36c3fef2.akstat.io, 54-154-186-178_s-23-203-249-81_ts-1604425586-clienttons-s.akamaihd.net, 54-154-186-178_s-23-203-249-81_ts-1604429882-clienttons-s.akamaihd.net, 54-154-186-178_s-23-203-249-90_ts-1604425341-clienttons-s.akamaihd.net, 54-154-186-178_s-23-203-249-90_ts-1604425577-clienttons-s.akamaihd.net, 54-154-186-178_s-23-203-249-90_ts-1604425679-clienttons-s.akamaihd.net, 54-154-186-178_s-23-203-249-90_ts-1604427498-clienttons-s.akamaihd.net, 54-154-186-178_s-23-203-249-90_ts-1604431774-clienttons-s.akamaihd.net, 54-154-186-178_s-92-123-142-66_ts-1604427735-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-81_ts-1604425115-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-81_ts-1604427273-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-81_ts-1604427303-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-81_ts-1604427359-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-81_ts-1604431429-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-81_ts-1604431547-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-81_ts-1604435637-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-90_ts-1604427151-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-90_ts-1604429503-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-90_ts-1604429594-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-90_ts-1604433473-clienttons-s.akamaihd.net, 54-246-30-86_s-23-203-249-90_ts-1604433539-clienttons-s.akamaihd.net, 54-246-30-86_s-88-221-134-224_ts-1604435698-clienttons-s.akamaihd.net, 54-246-30-86_s-95-101-129-96_ts-1604424926-clienttons-s.akamaihd.net, 54-246-30-86_s-95-101-129-96_ts-1604424989-clienttons-s.akamaihd.net, 54-75-39-103_s-23-203-249-81_ts-1604425265-clienttons-s.akamaihd.net, 54-75-39-103_s-23-203-249-81_ts-1604425415-clienttons-s.akamaihd.net, 54-75-39-103_s-23-203-249-90_ts-1604425504-clienttons-s.akamaihd.net, 54-75-39-103_s-95-101-143-24_ts-1604432234-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-81_ts-1604424935-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-81_ts-1604425058-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-81_ts-1604425120-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-81_ts-1604425189-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-81_ts-1604427540-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-90_ts-1604424875-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-90_ts-1604425270-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-90_ts-1604427110-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-90_ts-1604429433-clienttons-s.akamaihd.net, 54-75-41-190_s-23-203-249-90_ts-1604429456-clienttons-s.akamaihd.net, 54-75-41-190_s-92-123-140-11_ts-1604427291-clienttons-s.akamaihd.net, 54-75-41-190_s-92-123-140-11_ts-1604427412-clienttons-s.akamaihd.net, 54-75-41-190_s-95-101-129-96_ts-1604425019-clienttons-s.akamaihd.net, 54-75-41-190_s-95-101-143-18_ts-1604429529-clienttons-s.akamaihd.net, 684dd305.akstat.io, 684dd306.akstat.io, 684dd307.akstat.io, 684dd308.akstat.io, 684dd309.akstat.io, 684dd30a.akstat.io, 684dd30c.akstat.io, 684dd30d.akstat.io, 6852bd07.akstat.io, 6852bd08.akstat.io, 6852bd09.akstat.io, 6852bd0a.akstat.io, 6852bd0b.akstat.io, 6852bd0c.akstat.io, 6852bd0d.akstat.io, 6852bd0e.akstat.io, 6852bd0f.akstat.io, 6852bd10.akstat.io, 6852bd11.akstat.io, 6852bd12.akstat.io, 6852bd13.akstat.io, 6852bd14.akstat.io, 685d5b18.akstat.io, 685d5b19.akstat.io, 685d5b1b.akstat.io, 686eb51b.akstat.io, 686eb704.akstat.io, bcsecure01-a.akamaihd.net, brightcove04pmdo-a.akamaihd.net, ds-aksb-a.akamaihd.net, el24ucyccuqvax5bs2kq-pblhb6-a723eeea5-clientnsv4-s.akamaihd.net, el24ucyccuqvax5bt4yq-ptbmxa-6ef8e4803-clientnsv4-s.akamaihd.net, el24ucyccuqwcx5bs4uq-p03zy7-676237e5e-clientnsv4-s.akamaihd.net, el3lnwiccuqvax5bstvq-pch0tk-1cdf76638-clientnsv4-s.akamaihd.net, el3lnwiccuqvax5buy2q-pqnfkn-f673b4feb-clientnsv4-s.akamaihd.net, el3lnwiccuqvax5buzkq-pl30i3-08d7d87df-clientnsv4-s.akamaihd.net, el3lnwiccuqwcx5bu4ya-pyg66y-cb19a994e-clientnsv4-s.akamaihd.net, el3lnwiccuqxax5bstjq-puyi2b-1f022524f-clientnsv4-s.akamaihd.net, el3lnwiccuqxax5bsuua-pioden-695058c8f-clientnsv4-s.akamaihd.net, el3lnwiccuqxax5bsvta-pqns0s-b6979dbf5-clientnsv4-s.akamaihd.net, el3lnwiccuqxax5btzpq-pbifp1-07760bdf0-clientnsv4-s.akamaihd.net, el3lnwiccuqxax5bu23q-p2ez1a-7d289db29-clientnsv4-s.akamaihd.net, el3lnwixzp4swx5bs5pq-pnfw20-03cb87b70-clientnsv4-s.akamaihd.net, el3lnwixzp4swx5bsryq-p52tb9-f3dab0dd0-clientnsv4-s.akamaihd.net, el3lnwixzp4swx5bu35q-pdannf-fd1139023-clientnsv4-s.akamaihd.net, el3lnwixzp4swx5buxna-pyccr1-f710a073b-clientnsv4-s.akamaihd.net, el3lnwky3wdkax5bsxbq-p3hn9l-a2a7437e4-clientnsv4-s.akamaihd.net, el3lnwky3wdkex5bt23a-pfcryk-8b7c1430e-clientnsv4-s.akamaihd.net, elzm742y3wdkex5bs4lq-p0p40d-3a2e745b5-clientnsv4-s.akamaihd.net, elzm742y3wdkex5bzofa-pqb527-96b6b1fc9-clientnsv4-s.akamaihd.net, elzm74yccuqvax5b2szq-pf5z0b-8e0fe713e-clientnsv4-s.akamaihd.net, elzm74yccuqvax5bs5nq-pt4puj-60e29ce0a-clientnsv4-s.akamaihd.net, elzm74yccuqvax5bzo4a-ptxi68-223a872ab-clientnsv4-s.akamaihd.net, elzm74yccuqwcx5b2r3a-p84t0a-b5b6d0cb9-clientnsv4-s.akamaihd.net, elzm74yccuqwcx5btaca-p2p13t-2edd5f4d6-clientnsv4-s.akamaihd.net, elzm74yccuqwcx5buakq-p7s1ie-7095e2510-clientnsv4-s.akamaihd.net, elzm74yccuqxax5b2o7q-partxm-0ba99e22d-clientnsv4-s.akamaihd.net, elzm74yccuqxax5bs6fa-pnivpg-c492934bb-clientnsv4-s.akamaihd.net, elzm74yccuqxax5bt5qq-pcrjf9-bdc24fa26-clientnsv4-s.akamaihd.net, elzm74yccuqxax5bzp4q-pkl6rx-fb475a90e-clientnsv4-s.akamaihd.net, elzm74yxzp4swx5bs4ga-p9xzbs-ed47165ae-clientnsv4-s.akamaihd.net, elzm74yxzp4swx5bs7cq-p4s4el-cd1a19887-clientnsv4-s.akamaihd.net, elzm74yxzp4swx5bt4ka-p0qvim-2e8a5e71e-clientnsv4-s.akamaihd.net, elzm74yxzp4swx5bt6hq-pzy1yp-35d9d01e0-clientnsv4-s.akamaihd.net, elzm74yxzp4swx5bt7mq-p1duy0-1060998fa-clientnsv4-s.akamaihd.net, elzm74yxzp4swx5bucja-p0twy9-19851792c-clientnsv4-s.akamaihd.net, elzm74yxzp4swx5bzqza-pn76ir-1c0c55ff7-clientnsv4-s.akamaihd.net, elzm74yxzp4swx5bzsda-pqodge-888ec876f-clientnsv4-s.akamaihd.net, g2nlvmqcchiscx5bva5a-pwotro-14b66ca5a-clientnsv4-s.akamaihd.net, g2nlvmqccuqvax5bs7hq-p4vzcl-ad59a5fd9-clientnsv4-s.akamaihd.net, g2nlvmqccuqxax5bsz6q-pm3a6a-3feb7d021-clientnsv4-s.akamaihd.net, g2nlvmqxzp4swx5bs5uq-pd12b9-62c8cb38d-clientnsv4-s.akamaihd.net, g2nlvmqxzp4swx5bt3va-p7puv0-d4fafcfea-clientnsv4-s.akamaihd.net, g2nlvmsy3wdkax5bs5zq-p675cj-d0b1fd299-clientnsv4-s.akamaihd.net, g33b4vqccuqvax5btwhq-pfp8ei-5c0ea4329-clientnsv4-s.akamaihd.net, g33b4vqccuqvax5btytq-pupet4-0083df35c-clientnsv4-s.akamaihd.net, g33b4vqccuqvax5btzpq-pr1f2f-01d5fb765-clientnsv4-s.akamaihd.net, g33b4vqccuqvax5bvzcq-phk9tj-828709858-clientnsv4-s.akamaihd.net, g33b4vqccuqvax5bw2bq-py1x2v-a7310f6e5-clientnsv4-s.akamaihd.net, g33b4vqccuqvax5bx3za-pge3ox-a91a32353-clientnsv4-s.akamaihd.net, g33b4vqccuqwcx5bu4na-pqdvvi-3aaa5c611-clientnsv4-s.akamaihd.net, g33b4vqccuqwcx5bwzaq-pvw5k6-d3e3dcd05-clientnsv4-s.akamaihd.net, g33b4vqccuqwcx5bx22q-p8kovq-e038e0c0c-clientnsv4-s.akamaihd.net, g33b4vqccuqxax5bstpa-p4rsfx-bd0382a30-clientnsv4-s.akamaihd.net, g33b4vqccuqxax5btyeq-poz8cc-9955b8a36-clientnsv4-s.akamaihd.net, g33b4vqxzp4swx5bu27q-pxv1vf-89db7a111-clientnsv4-s.akamaihd.net, g33b4vqxzp4swx5bv25q-pt8447-731cc407d-clientnsv4-s.akamaihd.net, g33b4vsy3wdkax5bswnq-plqmrf-ff7289811-clientnsv4-s.akamaihd.net, g33b4vsy3wdkex5bsuoq-p56ka1-9bf23f300-clientnsv4-s.akamaihd.net, gzfsozyccuqwcx5bs3dq-p2yzo8-69eb1f4d7-clientnsv4-s.akamaihd.net, gzfsozyccuqwcx5bs4qa-p299q7-a9521f4ee-clientnsv4-s.akamaihd.net, gzfsozyccuqwcx5bsyyq-pv69oz-aed1b09c6-clientnsv4-s.akamaihd.net, gzfsozyccuqwcx5bwfuq-pw4gfb-c2c42381f-clientnsv4-s.akamaihd.net, gzfstpqccuqvax5bssvq-p0x8hm-7a3d7367f-clientnsv4-s.akamaihd.net, gzfstpqccuqvax5bsxsq-p2oajs-b2e67f00b-clientnsv4-s.akamaihd.net, gzfstpqccuqvax5bsy3a-pfuzjd-60f8ba5de-clientnsv4-s.akamaihd.net, gzfstpqccuqvax5bu2ia-p6uwyn-30e7a92df-clientnsv4-s.akamaihd.net, gzfstpqccuqwcx5bswqa-pplxq4-ee58ceb89-clientnsv4-s.akamaihd.net, gzfstpqccuqwcx5bu3mq-p6qff7-f4c4075e7-clientnsv4-s.akamaihd.net, gzfstpqccuqwcx5buz4q-pbk4m8-d20c90e54-clientnsv4-s.akamaihd.net, gzfstpqccuqxax5bt4ka-p3fi1s-1fcad7cd5-clientnsv4-s.akamaihd.net, gzfstpqxzp4swx5bsttq-p683qt-2c3f6e21e-clientnsv4-s.akamaihd.net, gzfstpqxzp4swx5bsu5q-pyioyl-3b5424f35-clientnsv4-s.akamaihd.net, gzfstpqxzp4swx5bsvra-ps8whv-800c4ca06-clientnsv4-s.akamaihd.net, gzfstpqxzp4swx5bt2ka-p3owfu-9bef421db-clientnsv4-s.akamaihd.net, gzfstpqxzp4swx5btynq-p80cg4-5fbda6ae3-clientnsv4-s.akamaihd.net, gzfstpsy3wdkax5btvta-pc4hb3-c24fbde0b-clientnsv4-s.akamaihd.net, i03f9f400-ds-aksb-a.akamaihd.net, i03fa4400-ds-aksb-a.akamaihd.net, i03faac00-ds-aksb-a.akamaihd.net, i03fae300-ds-aksb-a.akamaihd.net, i03fb4f00-ds-aksb-a.akamaihd.net, i22f29600-ds-aksb-a.akamaihd.net, i22f44600-ds-aksb-a.akamaihd.net, i22f47c00-ds-aksb-a.akamaihd.net, i22f4a100-ds-aksb-a.akamaihd.net, i22f55c00-ds-aksb-a.akamaihd.net, i22f5ca00-ds-aksb-a.akamaihd.net, i22f6b100-ds-aksb-a.akamaihd.net, i22f7bf00-ds-aksb-a.akamaihd.net, i22fdb800-ds-aksb-a.akamaihd.net, i22fdd700-ds-aksb-a.akamaihd.net, i3430c200-ds-aksb-a.akamaihd.net, i34d04400-ds-aksb-a.akamaihd.net, i34d71700-ds-aksb-a.akamaihd.net, i36486200-ds-aksb-a.akamaihd.net, i364b2700-ds-aksb-a.akamaihd.net, i369aba00-ds-aksb-a.akamaihd.net, i36d85900-ds-aksb-a.akamaihd.net, i36d86800-ds-aksb-a.akamaihd.net, i36e56b00-ds-aksb-a.akamaihd.net, i36f61e00-ds-aksb-a.akamaihd.net, i36f6c000-ds-aksb-a.akamaihd.net, i3f23f800-ds-aksb-a.akamaihd.net, ib0225600-ds-aksb-a.akamaihd.net, s.go-mpulse.net, trial-eum-clientnsv4-s.akamaihd.net, trial-eum-clienttons-s.akamaihd.net, warfnl2y3wdkex5buhra-pvnsej-42dd2535b-clientnsv4-s.akamaihd.net, warfnlyccuqvax5bvjta-pivu9l-324052216-clientnsv4-s.akamaihd.net, warfnlyccuqxax5bwjua-pt5xj8-63e5f59c4-clientnsv4-s.akamaihd.net, warfnlyxzp4swx5bugca-p9ihiy-2a56daf9f-clientnsv4-s.akamaihd.net, warfnlyxzp4swx5buiqq-p5eemy-20706e9d7-clientnsv4-s.akamaihd.net To provide the optimized image quality and enhance page loading speed | To provide the optimized image quality and enhance page loading speed |

| Amazon (Cloud Front) |

Amazon (Cloud Front) d15mv1adrb1s6e.cloudfront.net, d1vp9jkpfdwr15.cloudfront.net, d25jv1xpupcva6.cloudfront.net, d2cmqkwo8rxlr9.cloudfront.net, d2m3ikv8mpgiy8.cloudfront.net, d334tbn9icrqnt.cloudfront.net, d38nbbai6u794i.cloudfront.net, d3dvvd5arbl3b4.cloudfront.net, d3nkfb7815bs43.cloudfront.net, d9qz450atvita.cloudfront.net To speed up the delivery of your static content (e.g., images, style sheets, JavaScript, etc.) to viewers across the globe | To speed up the delivery of your static content (e.g., images, style sheets, JavaScript, etc.) to viewers across the globe |

| Brightcove | admin.brightcove.com, metrics.brightcove.com, players.brightcove.net, sadmin.brightcove.com, vjs.zencdn.net | To support video streaming |

These cookies gather information about your browser habits. They remember that you've visited our website and share this information with other organizations such as advertisers.

| Cookie | Domain |

|---|---|

| atdmt.com, connect.facebook.net, cx.atdmt.com, facebook.com, www.facebook.com | |

| Google Advertising | ad.doubleclick.net, adservice.google.com, adservice.google.ie, cm.g.doubleclick.net, doubleclick.net, googleads.g.doubleclick.net, pubads.g.doubleclick.net, static.doubleclick.net, stats.g.doubleclick.net, www.googleadservices.com |

| s.ytimg.com, www.youtube.com, youtube.com | |

| ads.linkedin.com, linkedin.com, px.ads.linkedin.com, www.linkedin.com |

Cookies are small files that store information on your computer, TV, mobile phone, or other device. They enable the entity that put the cookie on your device to recognize you across different websites, services, devices, and/or browsing sessions.